Operate simplely and directly

UH series Industrial HMI

Configuration software:Uniface

Efficient interaction

Rich interfaces

4.3' 7'and 10'

Customized interface

Data visualization

Makes production process easy to control

UH 400 SERIES

View allUH 500 SERIES

View allALL-IN-ONE

View all

Frequently Asked Questions About HMI panels

Regarding the frequently asked questions about industrial hmi, we only made a series of video and text content. If you encounter these problems, you may wish to take a look at these materials, they will give you some answers. If these contents still can not give you the answer, please contact us.

More Reasons to Choose UniMAT

-

![]()

High-tech enterprise

Complete certifications, a renowned PLC company in China

-

![]()

Direct manufacturer

Customization, OEM/ODM support, strong R&D capabilities

-

![]()

2000㎡ Warehouse

Full inventory, fast delivery, 3-year warranty, high quality

What is HMI (Human Machine Interface)

HMI, also known as human-machine interface, is a device that can receive instructions and feedback from the PLC that controls process automation equipment. It can also be understood as a user interface or dashboard that connects people to machines, systems or equipment. HMI is most commonly used in the field of industrial control.

HMI panels is usually connected to a programmable logic controller (PLC), which is responsible for controlling the process based on the input of the HMI and field sensors. HMI can provide information to relevant operators and allow relevant personnel to enter commands and transmit the instructions to the PLC for implementation.

In simple terms, hni panels is the matchmaker needed for communication between people and machines. Without this matchmaker, it is difficult for people and machines to communicate.

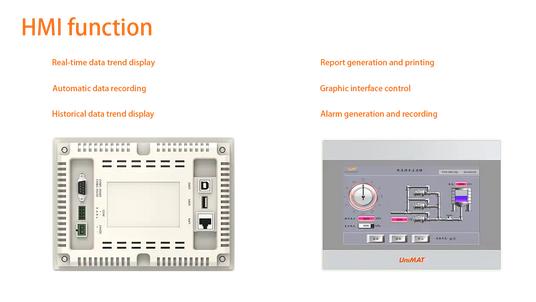

What are the functions of HMI panels?

There are many types of HMI interfaces, including RS232, RS485, and RJ45 network cable interfaces. For example, in a factory, we need to collect information such as temperature, humidity, and the status of machines in various areas of the factory, monitor and record these parameters through a main controller, and be able to handle some unexpected situations when they occur. This is a very typical application of HMI. Generally speaking, the HMI system must have several basic capabilities:

Common uses and fields of HMI panels

HMI (Human-Machine Interface) can be applied to many different scenarios and industries, including but not limited to the following aspects:

HMI (Human-Machine Interface) can be applied to many different scenarios and industries, including but not limited to the following aspects:

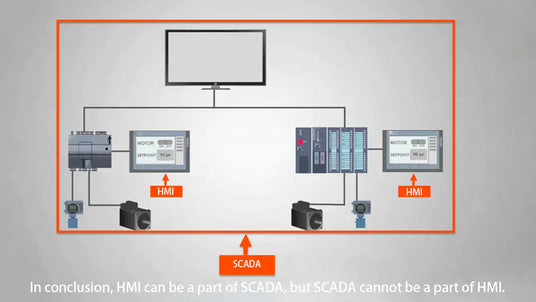

Difference between HMI and SCADA

A human machine interface (HMI) is a user interface that allows a human operator to interact with a machine or process. HMIs are commonly used in industrial settings to allow operators to monitor and control processes, and are usually connected to a programmable logic controller (PLC), which is responsible for controlling the process based on input from the field HMI and sensors. The HMI simply provides information to the operator and allows them to enter commands, which are then sent to the PLC for implementation.